What is bond coat? Bond coat is supposed to be a polymeric bond agent intended to provide a solid substrate to secure the new plaster to the old plaster. The National Plasterers Council (NPC) states bond agents should not re-emulsify and must be installed per manufacturer’s instructions.

Why does GM Pools (GM) say bond coat equals hollow plaster? There are several reasons bond coat equals hollow plaster and some of them will be touched on in this post.

Want a guarantee against hollow plaster?

The first issue is the bond coat itself. There are more homebrew bond coats used than manufactured bond coats. What is a homebrew bond coat you ask? A homebrew bond coat is one that is made by a company using materials that are not designed to be used under water (such as mortar admixes) instead of using a manufactured bond coat that has test data supporting its use under water. As previously mentioned above, the NPC states bond coats must “not re-emulsify” and the “applicator must follow the manufacturer’s directions”. Since there is not a manufacturer in a homebrew bond coat there are no directions and this product is definitely not supported for use as a bond coat.

If you hire a company to replaster your pool and they use a homebrew bond coat, you will be on your own when it fails. You should never allow someone to replaster your pool with homebrew bond coat. Otherwise you will learn quickly why we say bond coat equals hollow plaster.

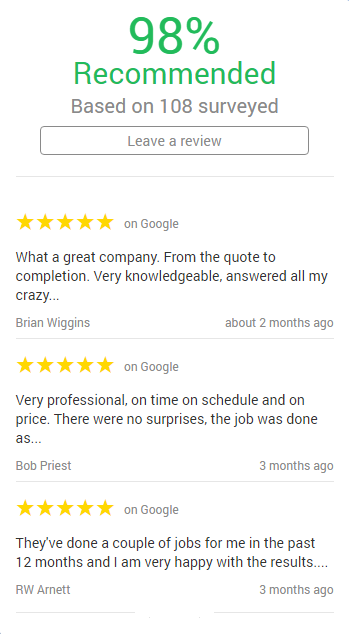

In GM’s experience, low bidders always use a homebrew bond coat and offer a unique warranty when it relates to the plaster install. These plaster applicators offer a 1-year workmanship warranty. Here at GM we like to politely call a 1-year workmanship warranty code for a “tail light guarantee.” This means your 1-year workmanship warranty is gone when you can no longer see their taillights as they drive away from your home. This equals to you, the customer, no longer having any sort of warranty. Choosing the low bidder, you will learn quickly why we say bond coat equals hollow plaster.

What about a manufactured bond coat you ask? While it is true manufactured bond coats are designed to be used under water and have test data to support their use, there is no guarantee your plaster will not go hollow. In general, the workers that prep pools for replaster are generally in a rush to get in and out of the pool (and on to the next job) versus being focused on the details and instructions. Manufactured bond coats require their directions for the install of the bond coat to be followed to achieve the product’s proven results. Manufactured bond coats must be mixed and installed exactly as the written instructions on the packaging. Using too much water or not allowing the material to set for the required length of time before installing the plaster can cause failure. The instructions also specify how long the material must cure prior to plaster installation. A bond coat should not be installed in a sporadic method with partial covering of the existing plaster. Bond coats are designed to cover 100% of the existing plaster. Do not install it to look like this.

It’s important to keep in mind, the same weather concerns that affect plaster application also affect bond coat application. If it is too wet, windy, or cold to plaster; it is also too wet, windy, or cold to install bond coat. In addition, bond coat manufactures require a specific number of days for the bond coat to cure after installation before the plaster can be installed. Most plaster applicators do not adhere to the manufactures’ instructions.

Next comes the issue of friable plaster. The NPC also states you must remove any loose and friable materials prior to installing the bond coat. What is a friable material you ask? See attached picture. Does the person quoting you to replaster your pool know what friable materials are? You should ask them. If they are not able to explain what this means, but are attempting to sell you on replastering you pool then isn’t it a pretty good idea that the crew coming out to plaster your pool doesn’t know what friable material means as well? Friable materials are loose flakes of plaster that are exposed in pool plaster when the cream layer is deteriorated. This scenario is very common on pools that need replastering.

The only way to remove friable material in plaster is to power wash the surface with 10,000 psi, sandblast the surface, or to #hydrodemoreplaster prep the surface. Acid washing will not remove the friable plaster. If you install bond coat over the loose and friable surface your bond coat and plaster will fail in the future. Why? There is not a true solid surface for the bond coat to adhere to.

A simple test to determine if the surface is friable is to scratch the surface with an old key like in this video.

The third issue is how many layers of plaster are present in your pool? Were those other layers of plaster currently in your pool installed according to the NPC standards for bond coat listed above? No plaster applicator truly has no way of knowing the answer to this question.

If plaster layers are not removed down to the original plaster layer, you are gambling that your new plaster investment won’t develop debonded plaster. What is debonded plaster you ask? Think of multiple layers of plaster like multiple layers of shingles on your roof. If your roof was leaking and had bald or damaged shingles would it make sense to cover up that leaky layer with a new layer of shingles? Of course not! You want to remove those layers and install the new layer of shingles directly on the roof sheeting. Hands down that is the best thing for a roof. That is also the best thing for your pool. You need to install the plaster directly on the shotcrete shell. Not over a leaky deteriorated plaster job that potentially has 1 or 2 more of the same deteriorated type of layers beneath it.

The last issue GM wants to point out about bond coat is the lack or false sense of confidence it creates. If plaster companies truly believed their process was the best, why is it they only offer a 1-year warranty? This is a warranty that does not even guarantee the bond of the plaster to the substrate. Why is that acceptable? You, as the customer has made the decision to make a sizable financial investment in your backyard…is a 1-year warranty enough? GM does not.

A large successful pool plaster applicator in California prepped all their pools with a manufactured bond coat. This plaster applicator installed the bond coat exactly as directed. They believed in their process and had used it for several years. Something changed…the plaster applicator had issues develop in several pools; five (5) months after install the plaster began debonding in several pools. When the plaster applicator contacted the manufacturer, the manufacturer did not stand behind their bond coat. They claimed the plaster applicator caused the problem. The plaster applicator had used this particular bond coat in far more pools than in the ones that had failure (from a bond coat aspect); and interestingly saw each of these pools fail around the same length of time after install. The plaster applicator ended the relationship with the bond coat manufacturer based on their lack of support and their NOW belief that bond coat equals hollow plaster.

Do you want a 10-year bond guarantee?